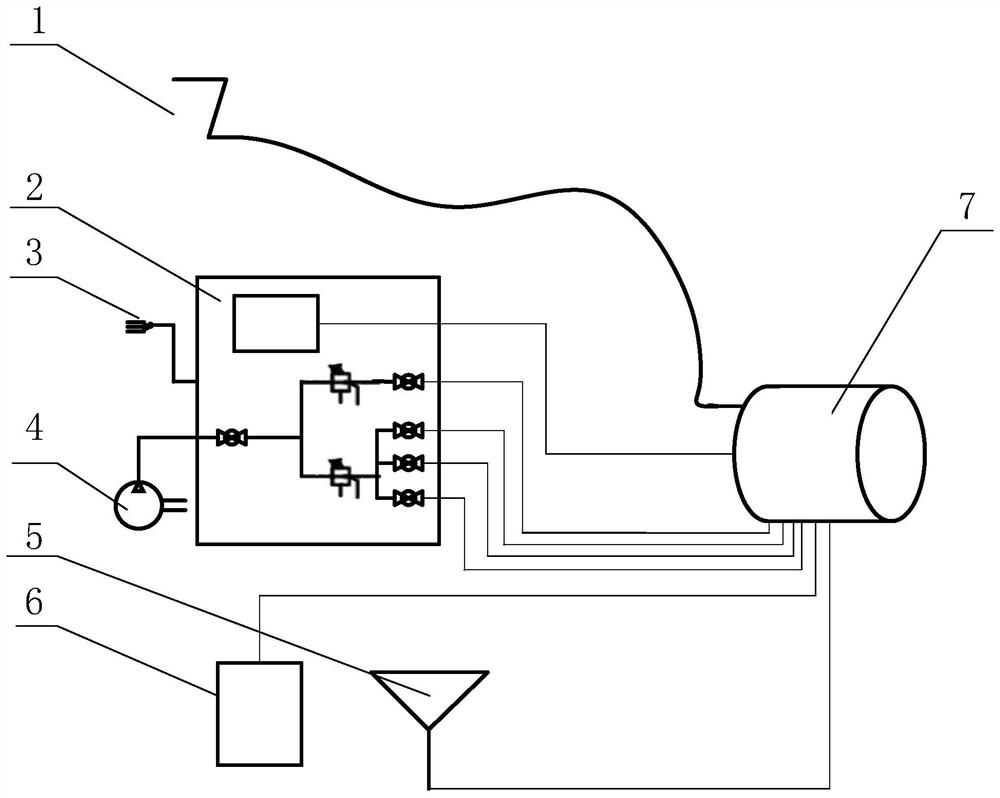

Nuclear power station mechanical penetration piece rust removal and corrosion prevention integrated device and working method

A technology for penetrating parts and nuclear power plants, which is applied in the field of integrated devices for rust removal and anti-corrosion coating in deep holes and narrow gaps of mechanical penetrating parts of nuclear power plants. dirty effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

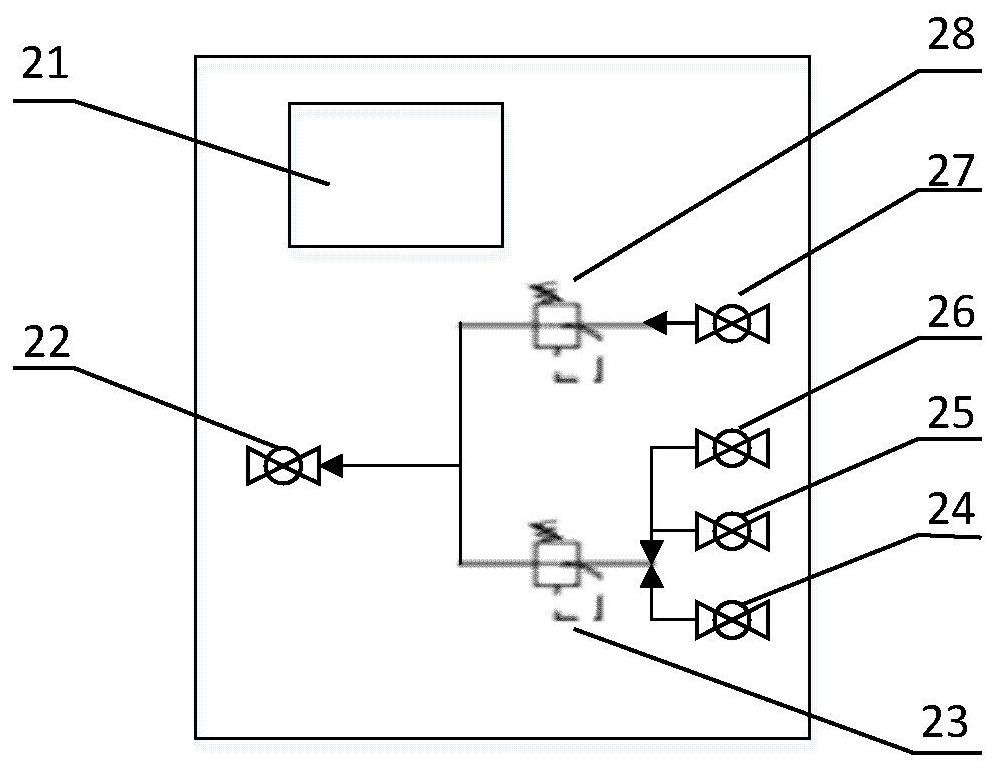

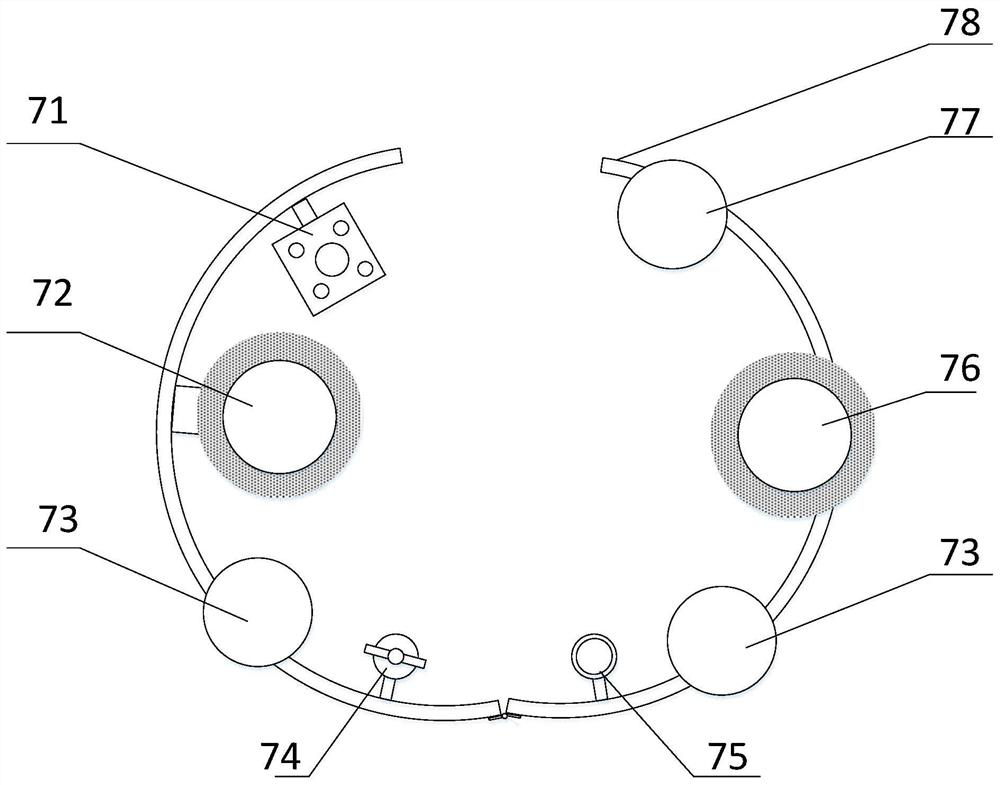

[0039] Example 1: The internal and external welds at the root of the penetrating member are corroded. Before using the present invention, prepare the anticorrosion coating paint, and connect the paint conveying pipeline. During the use of the present invention, the open-close cylinder support mechanism 78 is in a freely open state before it is placed in the through-piece workpiece, such as image 3 As shown, the open-close cylindrical support mechanism 78 surrounds the central pipe of the penetrating piece, and is closed to form a cylinder, such as Figure 4 As shown, the cylinder is retracted at this time, and the cylinder roller in the front section of the cylinder is retracted. At this time, the mechanism can be pushed into the inner wall of the outer pipe of the penetration to the bottom of the penetration. Start the air compressor, open the main air valve 22 and the cylinder switch 27 in the control mechanism, adjust the cylinder pressure to 0.4MPa through the cylinder p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap